|

Customer |

KAVLI WIRELESS INC |

|

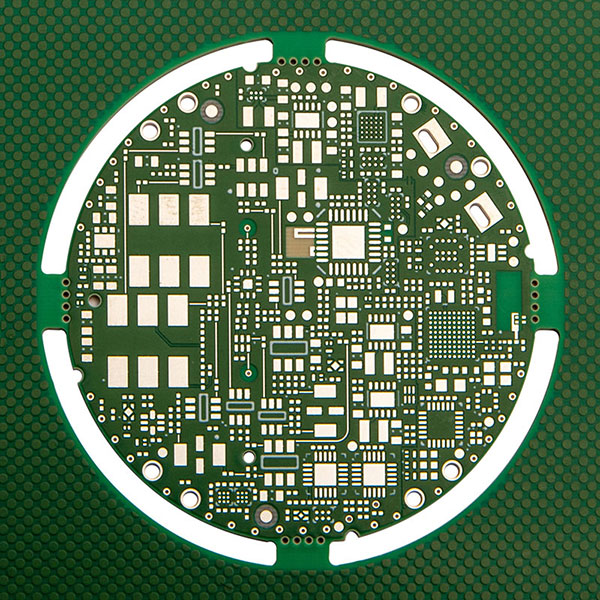

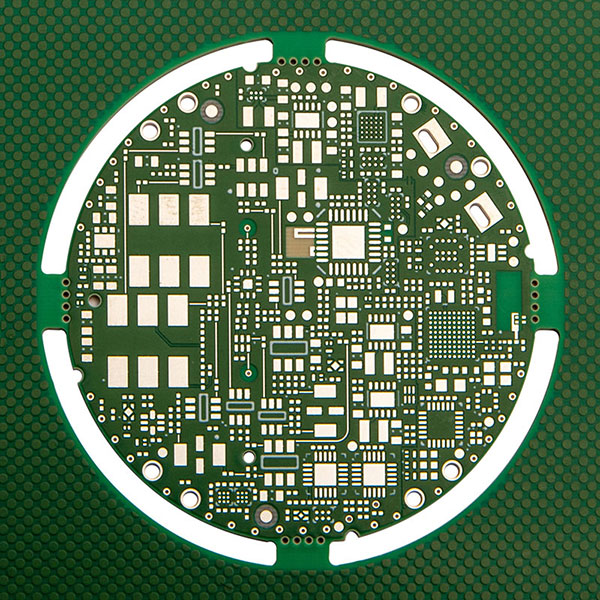

Application |

Our PCB is used for IoT Modules, Global Connectivity, Modem Intelligence Cloud |

|

Material |

EM-888BK |

|

Technical feature |

Immersion silver、Line width/line spacing:0.07/0.07 MM、Min via :0.15±0.03MM、Board thickness:0.882 MM、 Blind & buried hole |

|

Testing needed |

Thermal shock test、TG test、Metal surface contamination test |

|

About the customer |

Kavli Wireless, building the next generation of IoT connectivity management technology with their line of intelligent hardware, network access solution and modem management cloud. They work with Cellular network providers around the world to facilitate local connectivity, so that IoT product makers get to focus on what really matters to them - improving their customer experience, and forget about the hassles of getting their devices smart connected. |

|

About the PCB |

Steps HDI PCB |

This board is panalized by 6 pieces, surface treatment is Immersion Silver .

Silver precipitation is divided into the following three steps: pre leaching, silver precipitation and final deionized water washing. There are three purposes for setting up the pre leaching, one is to use it as a sacrificial solution to prevent copper and other substances from entering the micro etching tank from polluting the silver precipitation solution, the other is to provide a clean copper surface for silver precipitation replacement reaction, so that the copper surface can obtain the same chemical environment and pH value as the silver precipitation solution.

IoT is the developing trend in the future, camtech pcb is commited to provide the majority of IoT enterprises with high difficulty PCB solution, KAVLI WIRELESS INC is superior and the headquaters in USA that doing IoT Modules. Camtech pcb has cooperated with them from 2018, as a professional pcb fabricator, We do believe that pre-engineering talk before the final design can always ensure a good final product, KAVLI WIRELESS INC highly approves of the way that our company does, and let more and more PCB cases assigned to our company.