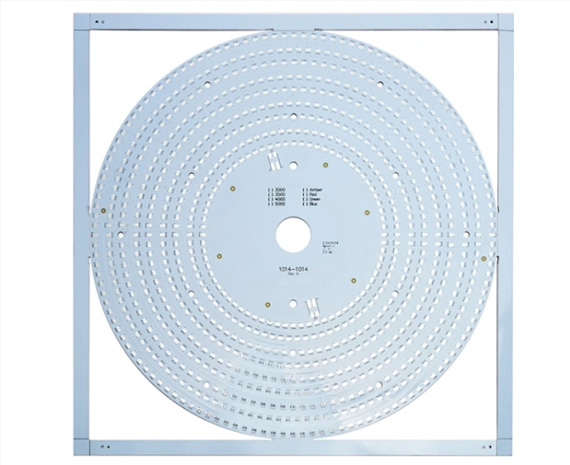

Aluminum printed circuit boards are also known as metal base PCBs, and are comprised of metal-based laminates covered by copper foil circuit layers. In addition, these aluminum PCBs have metal substrates instead of plastic substrates or fiberglass materials.

According to the construction and design, aluminum PCBs can be divided into different types.

Aluminum PCBs have many characteristics in same, such as that the main purpose is to provide heat dissipation solutions for the applications involving high temperature.

◈ Why is aluminum a good material for making circuit boards?

Aluminum is an ideal choice for heat dissipation of electronic components, which helps reduce any adverse effects that may occur on PCBs.

In addition, the aluminum material provides excellent durability and strength for electronic equipment, which is beyond the endurance of glass fiber and ceramic base.

◈ Copper etching

Aluminum PCBs have copper foil, usually thicker. Therefore, if the copper foil looks more than 3 oz, width compensation for etching is critical.

If the PCB does not meet the design requirements after etching for some reason, the wiring width will exceed the tolerance. Therefore, it is necessary to accurately design the wire width compensation. In addition, it is also important to control the etching process in the production process.

◈ Solder mask printing

The solder mask printing difficulty of aluminum PCB is usually due to the thick copper foil. This problem occurs because of the thickness of trace copper. Therefore, the copper thickness of the wiring will also cause image etching - which will result in a large difference between the bottom board and the wiring surface.

When this happens, solder mask printing becomes difficult. Therefore, it is very important to use secondary solder mask printing. In addition, it is also important to use high quality solder resist in this process. Or you can fill the resin before soldering the mask.

◈ Machinery manufacturing

In the process of mechanical manufacturing, you may encounter processes such as forming, V-notch, mechanical drilling, etc. These processes are usually on internal vias. As a result, it leads to a reduction in electrical strength.

Therefore, it is better to use professional milling cutter and electric milling for small batch products. In addition, it is also an ideal choice for adjusting drilling parameters to avoid burrs. In addition, it will help your machine manufacturing.

APPLICATIONS OF ALUMINUM PCBS

You can use aluminum PCB in the following aspects:

Camtech PCB has been engaged in the business of producing high-quality aluminum PCB for many years. Therefore, you can rely on our experience to provide first-class custom designed aluminum PCB to meet all your requirements. We can also process your order effectively at a price unmatched in the market. Please feel free to contact us for a free online quote and we can get started.

◈ Hot questions

1. What should be considered in the production of aluminum circuit boards?

Then, you need to consider aluminum design/circuit design and aluminum board. More important is the substrate, including insulating metal substrate and aluminum alloy substrate.

Then there are layers of circuit, such as aluminum base layer, insulating layer, aluminum film layer and conductive layer. In addition, physical properties are also important factors of aluminum PCB, such as thermal performance, thermal efficiency, operating temperature, etc.

In addition, your requirements for aluminum PCB applications are also important. Whether it is large-scale application, high-frequency aluminum PCB or LED application, radiator will have an impact on aluminum PCB.

In addition, pay attention to the conductive medium of aluminum plate, the basic structure and important components of aluminum core PCB. In addition, the manufacturing cost of the printed circuit board.

◈ Our certification

Here are the certificates we have:

IATF 16949:2016 ISO 9001:2015 ISO14001:2015 ISO13485:2016 UL In addition, all our products comply with IPC and ROHS standards. More importantly, we are always committed to manufacturing high-end PCB products.