Price

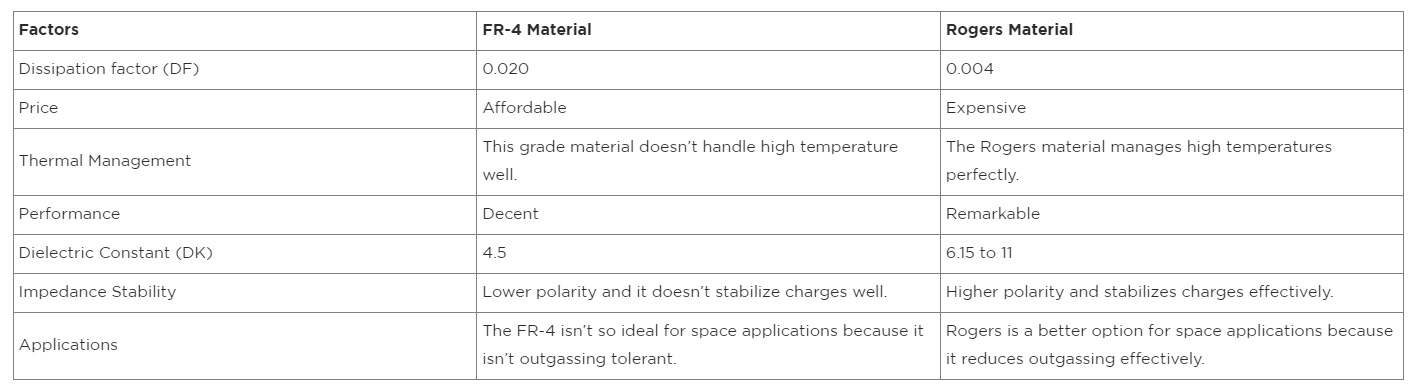

For the manufacture of printed circuit boards, the type of materials used is important, but the price is also important. FR-4 and Rogers materials differ in cost. FR-4 material is cheaper than Rogers material. You need to consider your product performance requirements, and then choose FR4 material or Rogers material.

However, if you need PCB made of cheap materials, you'd better choose PCB made of FR-4 materials. If your product needs high-performance PCB made of the best materials, you'd better choose PCB made of Rogers materials. You need to remember that Rogers materials may be the best choice, because cheap may eventually become expensive.

High frequency

Printed circuit boards made of FR-4 and rogers materials - whether they are made of rogers 4350 or rogers 4350b materials - are very popular due to their wide range of electronic applications.

Printed circuit boards made of FR-4 materials are preferred because they are low cost, reliable, and well known for their electrical and mechanical properties. They can be used in all fields, from microwave design to audio circuits. Unfortunately, printed circuit boards made of FR-4 materials are not suitable for high-frequency applications. Rogers made the most famous high-frequency special laminate. Compared with the printed circuit board made of FR-4 material, the dielectric constant of the material is reduced by nearly 20%.

The best way to determine whether your project will make better use of high-frequency laminates is to evaluate the mechanical and electrical requirements of the work. If you find that the range of electrical and mechanical changes is too large, you'd better choose Rogers materials

Df/Dissipation

In the manufacture of printed circuit boards, the type of material is the most important, although it may require a large cost. However, when it comes to the loss factor or Df, it is not the only problem to know the content value. Printed circuit boards made of FR-4 materials will be affected or reduced. Compared with PCB made of Rogers material, the loss is more significant.

In other words, FR-4 materials have higher dissipation factors than Rogers materials, especially at high frequencies. The typical value of PCB made of FR-4 material is about 0.020, while PCB made of Rogers material is close to 0.004. FR-4 materials can be identified by increased dissipation with increasing frequency. High frequency laminate mainly shows dissipation characteristics that are stable with frequency.

The low dissipation factor of FR-4 materials helps minimize signal loss. Don't forget that their compatibility with FR-4's automated assembly and processing makes them very easy to manufacture.

Impedance stability

Impedance is the resistance or measurement of current to energy flow when certain voltage is applied. A good example of impedance is the resistance line of a current. Stable impedance is essential for many designs, and this is where FR-4 and Rogers materials differ.

Although FR-4 materials are cheap, they are very susceptible to a wide range of changes in the dielectric constant of the substrate width and length, in addition to temperature changes. In conclusion, Rogers' materials have a wider range of dielectric constants than FR-4 content in terms of impedance stability.

If the circuit needs to work with small changes in a large temperature range, the high-frequency laminate is better. Here, you may have to choose PCB made of Rogers material instead of those made of FR-4 material, especially when most of your operations involve working in high temperature environment.

Dielectric constant

The dielectric constant is an effective measure of the ability of a material to store some electrical energy in an electric field. When it comes to the dielectric constant, the dielectric constant of FR-4 is about 4.5, which is far lower than that of Rogers materials with a dielectric constant of 6.15 to 11.

In other words, printed circuit boards made of materials containing high dielectric constant values can produce some small circuits. The printed circuit board made of FR-4 material can save more than 25%. Other reasons why FR-4 items are easy to use are that these redundant fireproof materials are light, moisture-proof and have high dielectric strength.

Although Rogers' material is suitable, you'd better use FR-4 material in terms of dielectric constant. Rogers 4350 and Rogers 4350b materials follow the same manufacturing process as FR-4 materials, although compared with Rogers PCB, FR-4 components can effectively store electric energy. The high dielectric constant itself is not so ideal.

Generally, printed circuit boards with high dielectric constant tend to be damaged quickly, especially in some of the strongest electric fields.

Space Applications

Space exploration has increased recently, and many countries are trying to send people into space. In space applications, the materials used to manufacture printed circuit boards are very important; Not all materials used in the production of printed circuit boards for space exploration have excellent functions.

Some materials may not work as expected. FR-4 and Rogers are two different materials in terms of applicability or space use. In space, there is deflation. Degassing occurs when residual gas is released from the powder coating during curing. Corrosive materials or moisture can effectively penetrate the surface through pinholes, damaging certain components.

Although FR-4 materials achieve an excellent balance in electrical stability, manufacturability, durability and cost, Rogers materials are still considered to be one of the best materials in this field in terms of space applications. In short, for almost all space exploration or use, they have low gas release.

Conclusion

The type of material on the printed circuit board is important. When selecting printed circuit boards, you need to select products made of the best products to ensure that you can obtain high-qualityresults and lasting effects. Camtech PCB is the best place to find excellent PCB production and manufacturing services.

Depending on the type of material you need, feel free to find them on the Camtech PCB. We have a team of experts who can use the industry's popular Rogers and FR-4 materials to provide you with an unforgettable manufacturing experience. For more details on PCB materials, please feel free to contact info@camtechcircuits.com Contact our support team.