Time | 5 days - 2 weeks |

Finished board thickness (flexible part, no stiffener) | 0.05-0.5mm (limit:0.5-0.8mm) |

Finished board thickness (rigid part) | 0.2-6.0mm |

Finished copper thickness | 0.5-5 oz |

Minimum Tracing/Spacing | 3mil/3mil |

Surface treatment | OSP HASL/OSP - RoHS lead/lead-free tin spraying ENIG/hard gold/immersion silver |

Impedance control | 310% |

Minimum laser hole | 0.1mm |

Minimum drilling diameter | 8mil |

Other technologies | HDI/Golden Finger/Stiffener (only applicable to PI/FR4 base plate) |

Rigid flexible PCB is preferred because:

Competitive price

◈ Our price is one of the most competitive in the world

◈ Own factory, good cost control, no hidden cost

◈ Accept T/T, cash, credit card, PayPal, bank transfer, etc.

◈ Our two factories have price support for different orders

On time and safe delivery

◈ Common methods include DHL and FedEX, and door-to-door service. The normal transportation time is only 2-4 days.

◈ Cooperate with two transportation companies for many years, with favorable price

◈ Anti static+moisture-proof+shockproof packaging; Certificate of inspection

◈ Professional agent to Iran and Pakistan

Quality assurance

◈ All products comply with IPC or UL standards and ROHS&REACH standards. 98% of customers have positive comments and satisfaction.

◈ Standardized factory processes and management

◈ Multiple detection services

Returns and Refunds

If our PCB cannot be used due to our fault, you can claim compensation.

◈ We can directly refund to your account or rework the circuit board that cannot be used or remanufacture your PCB and ship it to you again, but if you need to rework, please cooperate to solve the problem.

What is the minimum annular ring of the through hole in the rigid-flexible board technology?

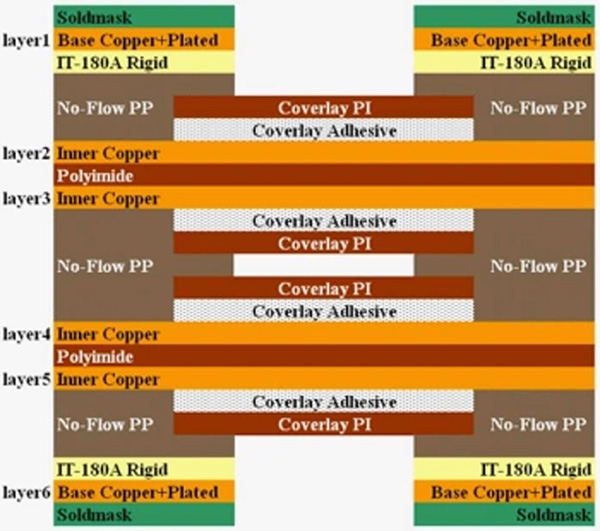

Can I get the stack diagrams from you?

MD assembly - are there any restrictions on the minimum/maximum dimensions of components with rigid flexible joints?

Can I view and process Altium CAD data directly?

Do you offer any discounts?