|

Customer |

LINKOLN TECHNOLOGY SOLUTIONS |

|

Application |

Our PCB is used for industrial LCD, medical LCD, Marine LCD, Advertising LCD, Automotive LCD |

|

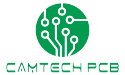

Material |

ISOLA 185HR |

|

Technical feature |

Asymmetric copper thickness,Min via :0.2±0.05MM |

|

Testing needed |

Sectioning analysis、Thermal Shock Test、 Thermal Stress test、Ionic Contamination Test |

|

About the customer |

Linkoln Technology Solutions is a Design Services and LCD Integration Company, focused on creating solutions with good performance. They have in-house engineering expertise in all disciplines with prototype manufacturing in NC, USA. All of their solutions focus on solving their customer’s challenges with a cost-effective, manufacturable product. They also offer turnkey production of their LCD solutions through wholly owned ISO 9001 Certified LCD factory |

|

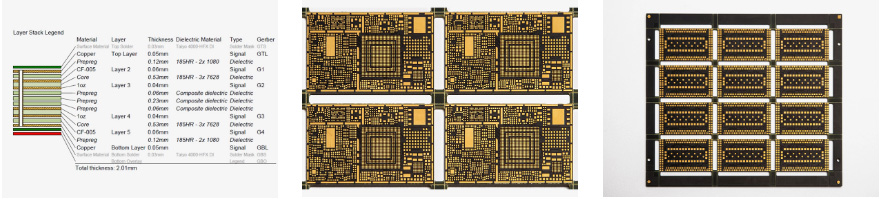

About the PCB |

High frequency mixed-pressure pcb board design |

This board is panalized by 2 pieces, high frequency mixed-pressure board.

The particularity for this board is mechanically drilled blind hole. Blind Vias: Connects an inner layer with the adjacent surface layer, they are only visible on one side of the boards and so are called 'blind' vias. Drill depth is extremely important in vias, because going too shallow or too deep can have a dangerous impact on the board. You can also create spurs and rough edges that cause issues if you’re not being careful.

Camtech PCB cooperated with LINKOLN TECHNOLOGY SOLUTIONS from 2015. For LINKOLN TECHNOLOGY SOLUTIONS provides special technical HDI board. As a focused on high density pcb fabricator, Camtech PCB do believe that pre-engineering talk before the final design can always ensure a good final product. For this many years , LINKOLN TECHNOLOGY SOLUTIONS highly praises the quality of our products and has been cooperating with us ever since.